Шариковые и роликовые подшипники Discovery 3

- ‹‹‹ Шаговый электродвигатель системы климат-контроля Range Rover 3

- Сетчатый фильтр маслоприёмника Freelander 1 ›››

When removing and installing bearings, ensure that the following practices are observed to ensure component serviceability:

ВНИМАНИЕ: Service tools have been developed for removing the majority of bearings; these must always be used where specified.

- Remove all traces from bearing under inspection by cleaning with a suitable degreasant; maintain absolute cleanliness throughout operations.

- Conduct a visual inspection for markings on rolling elements, raceways, outer surfaces of outer or inner surfaces of inner rings. Reject any bearings found to be marked since marking in these areas indicates onset of wear.

- Hold inner race of bearing between finger and thumb of one hand and rotate outer race to check that it revolves absolutely smoothly. Repeat holding outer race and rotating inner race. DO NOT spin the bearing.

- Rotate outer ring gently using a reciprocating movement whilst holding inner ring; feel for any check or obstruction to rotation. Reject bearing if movement is not absolutely smooth.

- Check bearing for blueing or signs of overheating.

- Lubricate bearing with the specified lubricant.

- Inspect bearing surface of shaft and bearing housing for discoloration or other markings which indicate overheating of bearing or movement between bearing and seating.

- Before fitting bearing, ensure that shaft and bearing housing are clean and free from burrs.

- If one bearing of a pair shows signs of wear, overheating etc., it is advisable to replace bearings as a pair unless it is suspected that one bearing may have been faulty when fitted, was fitted incorrectly or the fault arose due to oil seal failure.

- Never refit a bearing unless it is in a fully serviceable condition.

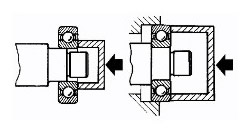

When fitting a bearing to a shaft, only apply force to the inner ring of the bearing. When fitting a bearing into a housing, only apply force to the outer ring of the bearing.

ВНИМАНИЕ: Service tools have been developed for fitting the majority of bearings; these must always be used where specified.

In the case of grease lubricated bearings, fill the space between the bearing and outer seal with the recommended grade of grease before fitting the seal.

ВНИМАНИЕ: When a waxed oil seal (fitted dry) type of oil seal is to be fitted, take great care that grease does not contaminate the running surface of the seal.

Always make suitable reference marks between the components of separable bearings e.g. taper roller bearings when disassembling to ensure correct location of components when assembling. Never fit new rollers in an outer ring, always fit a new bearing assembly.

Меняем подшипник задней ступицы на Ленд Ровер Дискавери 3 Land Rover Discovery 3

Воспринимаемые нагрузки подшипниками качения. Выбираем подшипник правильно

Лайфхак от Петровича. Проблемы с пневмой Discovery 3

LR Discovery 4 VS Discovery 3 Иллюзия обмана!

Land Rover Discovery 3 - Неисправности за 10 лет

Легендарный Ленд Ровер Дискавери 3 с пробегом 500000 км Отзыв владельца LR WEST